I am still trying to figure out the twisting mechanic of tying up hair, but I think I am getting closer with my third design. With Design 3, I created a half-cylindrical shape to guide the hair into the elastic. There is a small cylinder knob on each side of the half-cylinder. After working on the design in a few sessions, I created a cross divit in the knob so the elastic could latch to the knob, with the intent of stretching the elastic enough to get hair through it. There are holes on each side of the cylinder so that someone can reach their fingers under the elastic to twist the hair through.

As I was creating Design 3, I came up with a variation of this idea after watching a video of an amputee putting their hair up with a different tool. The tool they were using was brush-shaped and did not seem as effective, because it seemed like she was still struggling to get her hair up and it seemed like a loose ponytail. One thing that I did notice was that the tool had three prongs. The three prongs intrigued me as I was expecting her to use the prongs to tie the elastic by moving the elastic from one prong to another. I used the base of Design 3 and put the knobs on top of the cylinder instead of on the sides. I also used three knobs instead of two so that there was a knob available for switching the elastic from one twist to another.

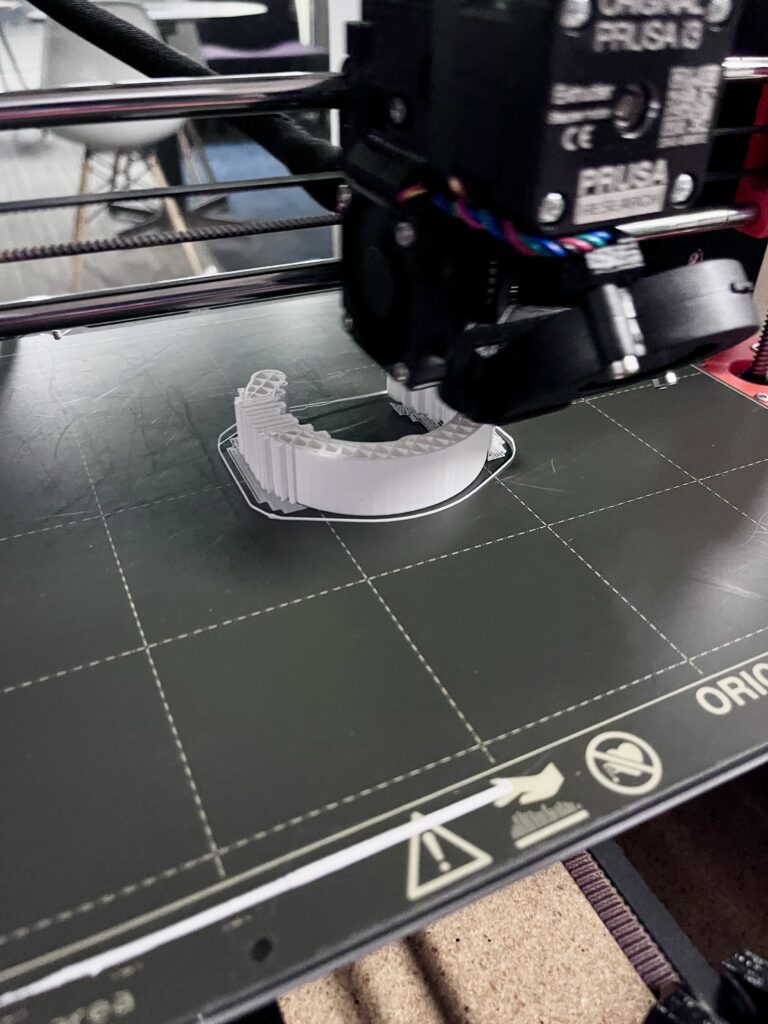

The one caveat of this design is that the holes in the sides for grabbing elastic force me to add supports to the model when I print it. Design 3 took 4 hours and 13 minutes, and Design 3.1 took 4 hours and 32 minutes. This is a big jump from my previous designs which took about an hour to an hour and a half, but in the 3D printing world, a 4-hour print is not awful.

This week I created Design 3 and 3.1 and printed each of them. I have yet to test them as the prints took almost 9 hours, but at the beginning of next week, I will be testing them, and then starting on the next iteration of model revision and printing!